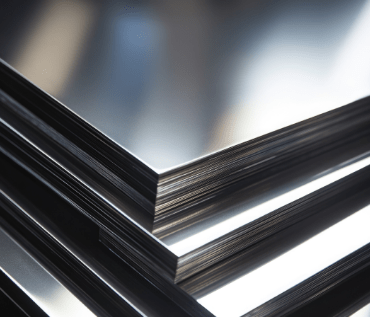

The Steel Company provides expert custom fabrication services for stainless steel products with Ti-PVD (Titanium Physical Vapor Deposition) coating. This high-performance coating process enhances the appearance, corrosion resistance, and wear resistance of stainless steel, making it a preferred choice for decorative and architectural applications.

From design to delivery, we offer precision engineering, cut-to-size customization, and surface finishing to meet your exact specifications.

Key Features

PVD-coated surfaces

Corrosion-resistant finish

Compatible with major fabrication processes

Custom shapes & sizes

Durable and scratch-resistant

Applications

- Architectural panels and cladding

- Elevator interiors and control panels

- Hotel and office interior elements

- Retail displays, kiosks, and counters

- Furniture trims and fixtures

- Bathroom and kitchen feature panels

Fabrication Capabilities

- Laser cutting

- CNC bending and shaping

- PVD surface coating

- Spot welding and edge grinding

- Drilling and polishing

We work with leading grades like SS 304, SS 316, and SS 201, ensuring structural integrity and aesthetic excellence.

PVD Coating Process

- Surface Preparation – Cleaning and prepping base stainless steel

- Vacuum Deposition – Thin-film PVD layer added under high heat

- Color & Texture Finalization – Depending on client-specified finish

- Quality Control – Measured for adhesion, durability, and visual consistency

- Packaging – Final product is safely packed for local or global delivery

FAQs

Is PVD coating durable?

Yes. PVD is highly resistant to scratches, corrosion, and fading. It’s perfect for long-term indoor or outdoor use.

Do you work with architects and contractors?

Yes. We often collaborate with design professionals to execute large-scale projects.

Can I request mirror or matte finishes?

Absolutely. We offer multiple finishes including mirror, hairline, matte, and brushed.

Are you able to fabricate based on CAD drawings?

Yes. Just share your technical drawings, and we’ll fabricate accordingly.

Is the coating available in different colors?

Yes. Gold, black, rose gold, blue, bronze, and more.

Custom Stainless Steel Fabrication with Finish You Can Trust

When it comes to custom stainless steel fabrication, detail and finish matter. At The Steel Company, we handle everything under one roof—from PVD coloring and CNC cutting to welding and polishing—ensuring you get the design precision and surface quality your project deserves.

Our PVD-coated fabrication parts are ideal for interior decor, branded panels, signage, elevators, and luxury retail fixtures.

Let’s bring your custom stainless steel design to life.

Get in touch for free consultation or to receive a fabrication quote tailored to your needs.