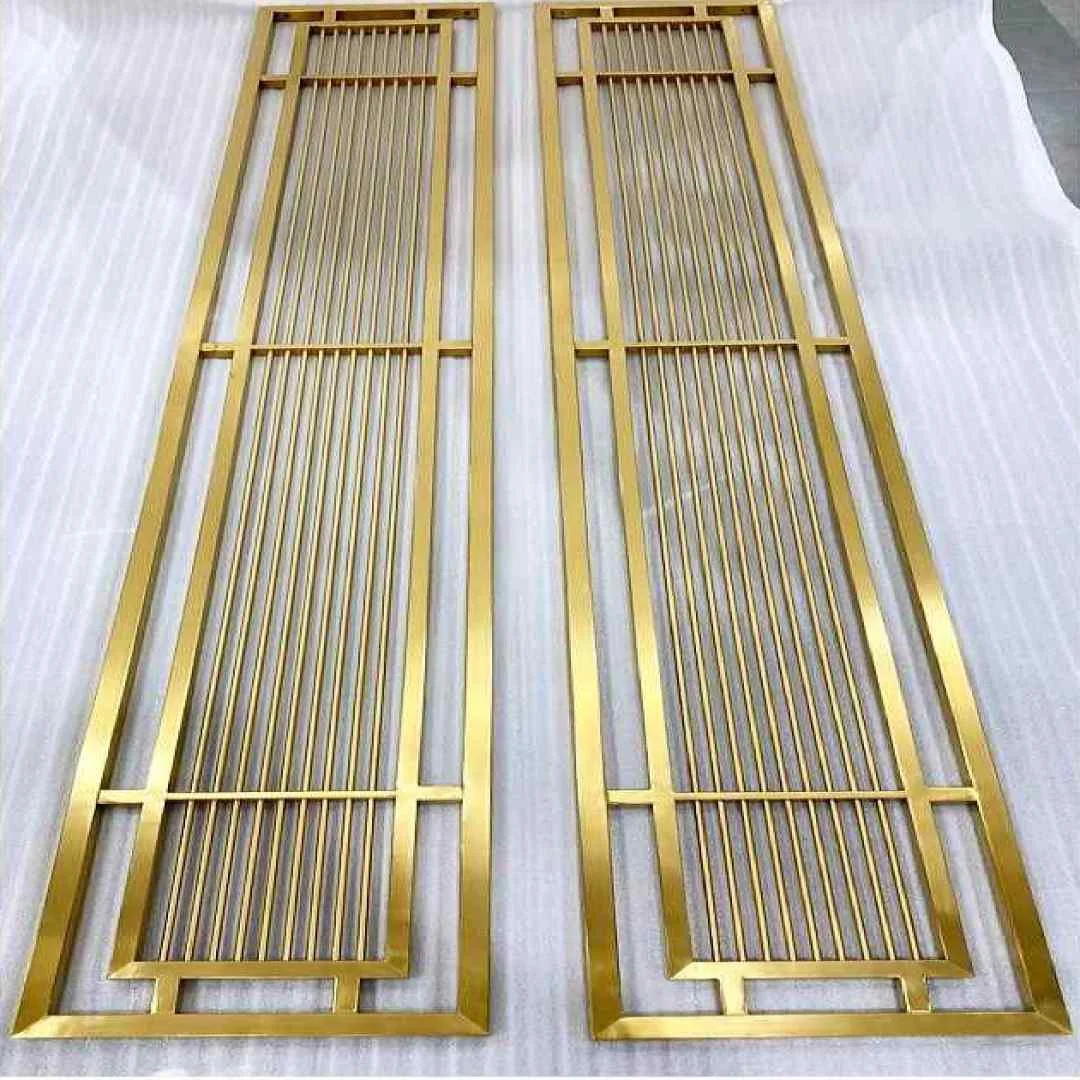

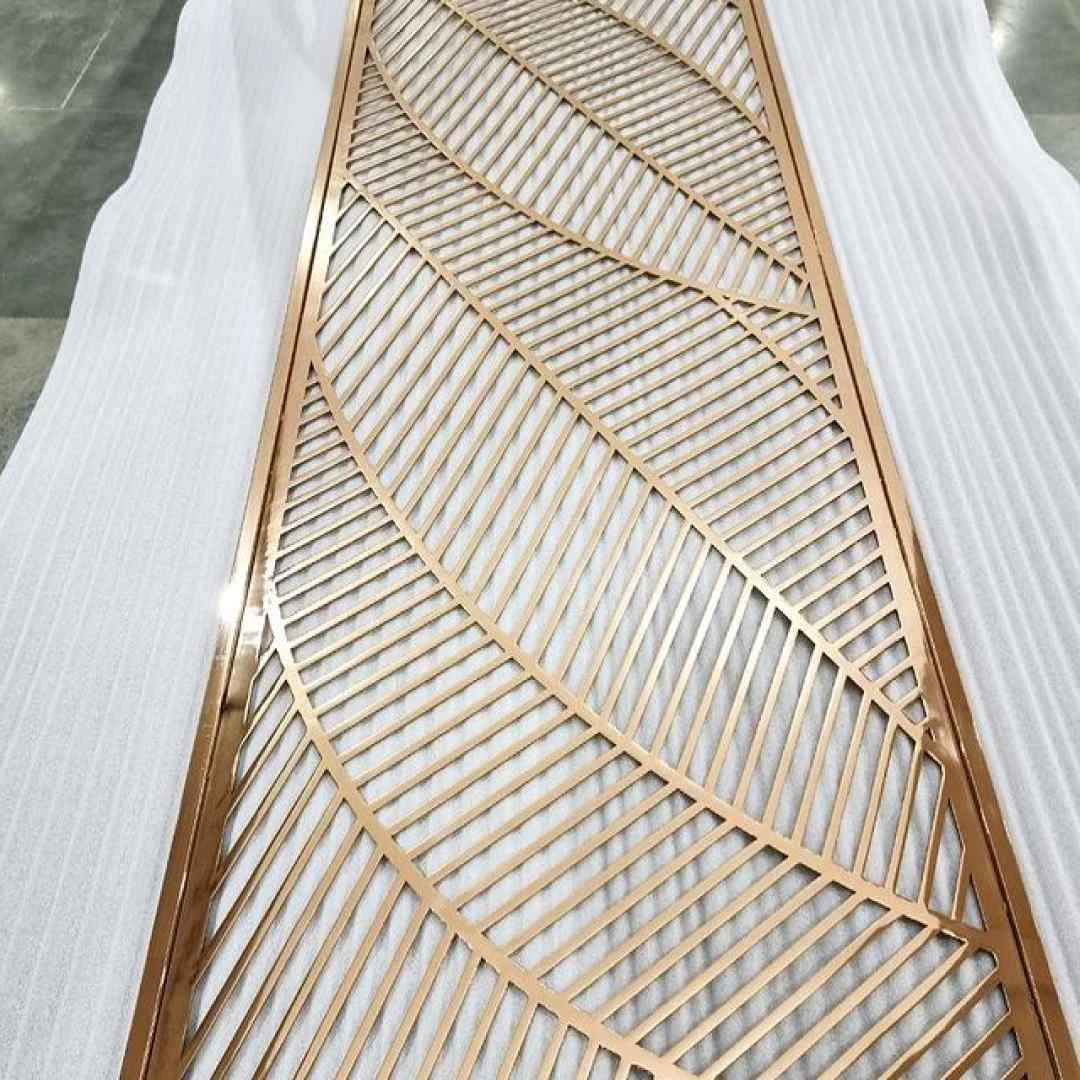

Stainless steel fabrication with PVD

At The Steel Company, we fabricate custom stainless steel parts and finish them in Ti-PVD (Titanium Physical Vapour Deposition). Work is completed in-house for tighter control: CNC cutting, forming, welding, polishing and colour coating. You get a refined look, consistent colour, and a finish that stands up to daily use.

Highlights

- Ti-PVD durability with strong resistance to scratching, corrosion and tarnish

- Finish library: mirror, hairline, brushed, satin, etched, or a custom texture

- Colour palette: gold, rose gold, bronze, black, champagne, blue

- Made to brief: shapes, sizes and details built to your drawings

- In-house capability: CNC cutting, bending, welding, edge finishing, laser etching

- Typical uses: elevators, wall panels, signage, furniture accents, luxury interiors

Best suited for

- Feature walls and reception cladding

- Elevator cabins, doors and COP surrounds

- Retail fixtures and brand walls with precise colour targets

- Furniture components that need a clean edge and stable sheen

Specifications

- Material grades: SS 201, SS 304, SS 316 (choose SS 316 for coastal or high-humidity sites)

- Thickness: 0.6 to 3.0 mm as standard; other gauges available

- Surface finishes: mirror, hairline, brushed, satin, etched

- Coating: Titanium PVD, vacuum deposited for a hard, colour-stable film

- Protection: PVC film on visible faces; grain direction noted for installers

- Fabrication: CNC cutting, bending, welding, edge polishing, pattern forming

- Customisation: cut to size, etched logos, repeating motifs, registration marks

- Packaging: protective pallets or wooden crates for transport

Formats and sizes

- Flat panels for walls, ceilings and decorative cladding

- Profiles and trims in U, L, T and V-groove for clean reveals

- Cut to size from your list; edges finished on CNC for neat joins

- Branding and patterning etched directly in the sheet for permanence

Build options

- Custom patterns with etching, embossing or laser cutting

- Furniture elements such as frames and legs with controlled polish

- Signage panels with crisp letterforms and colour-true faces

- Architectural pieces including façades, partitions and metal art

Handling and care

Use a soft cloth with a neutral pH cleaner. Avoid abrasive pads and bleach-based products. Keep the protective PVC film in place until installation is complete.

Ordering and lead time

Share drawings, quantities and finish targets. We will confirm grade, finish and colour, provide sample chips if required, and schedule production. Lead time depends on finish and volume and will be confirmed in your quote.